Just-in-Time

Just-in-Time (JIT) Inventory is a philosophy and approach to inventory management that has gained significant global recognition and adoption. Originating from Japan’s manufacturing industry, JIT focuses on eliminating waste, reducing lead times, and synchronizing production with customer demand. JIT aims to minimize inventory levels by receiving inventory just in time for production or customer delivery. Many organizations worldwide have implemented JIT principles to improve efficiency, reduce inventory holding costs, and enhance overall supply chain performance.

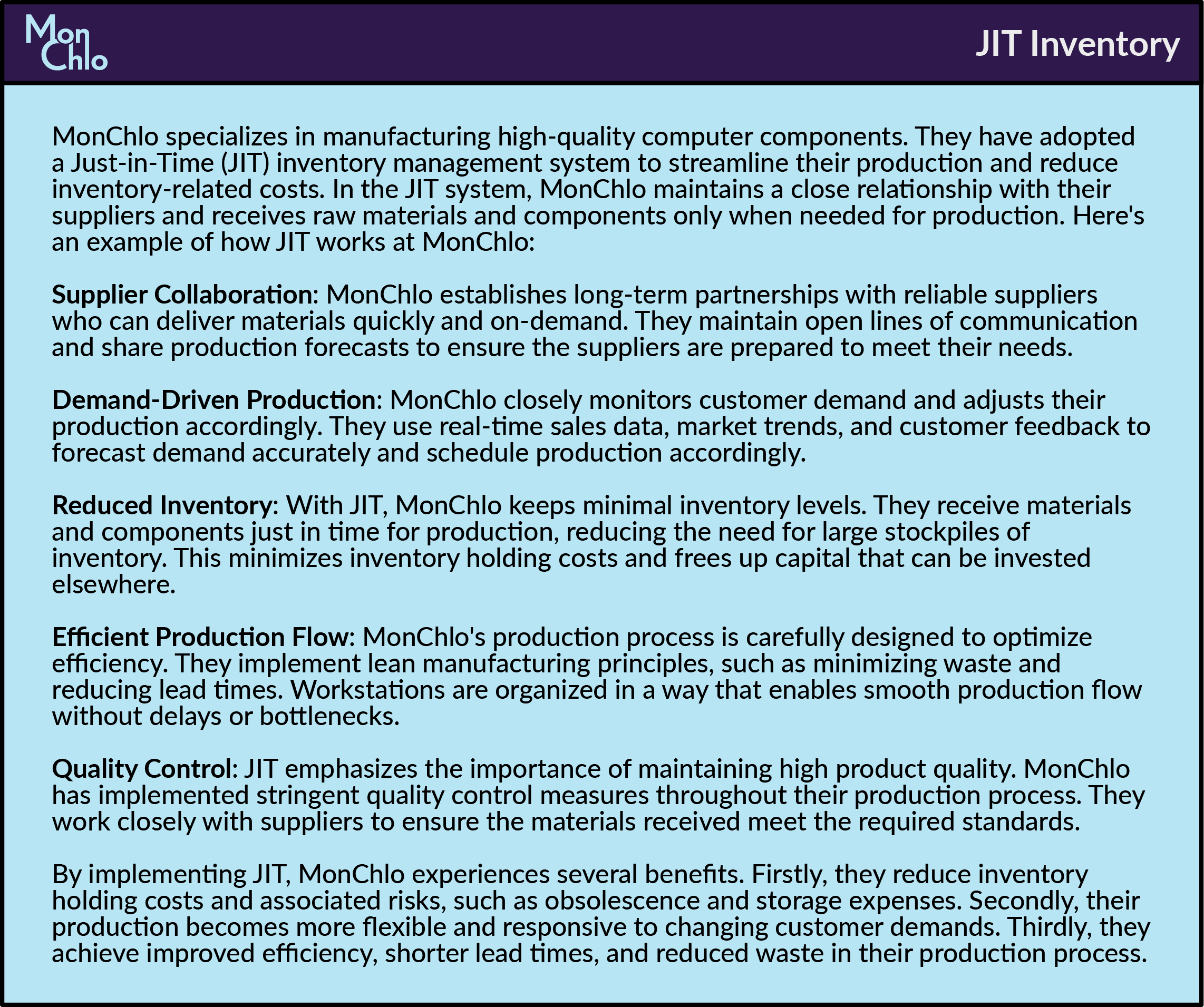

Here’s a case study illustrating the implementation of Just-in-Time (JIT) inventory management at MonChlo, our fictional technology company:

The JIT approach allows MonChlo to maintain a lean and agile supply chain, minimize costs, and deliver high-quality products to their customers in a timely manner.